Your cart is currently empty!

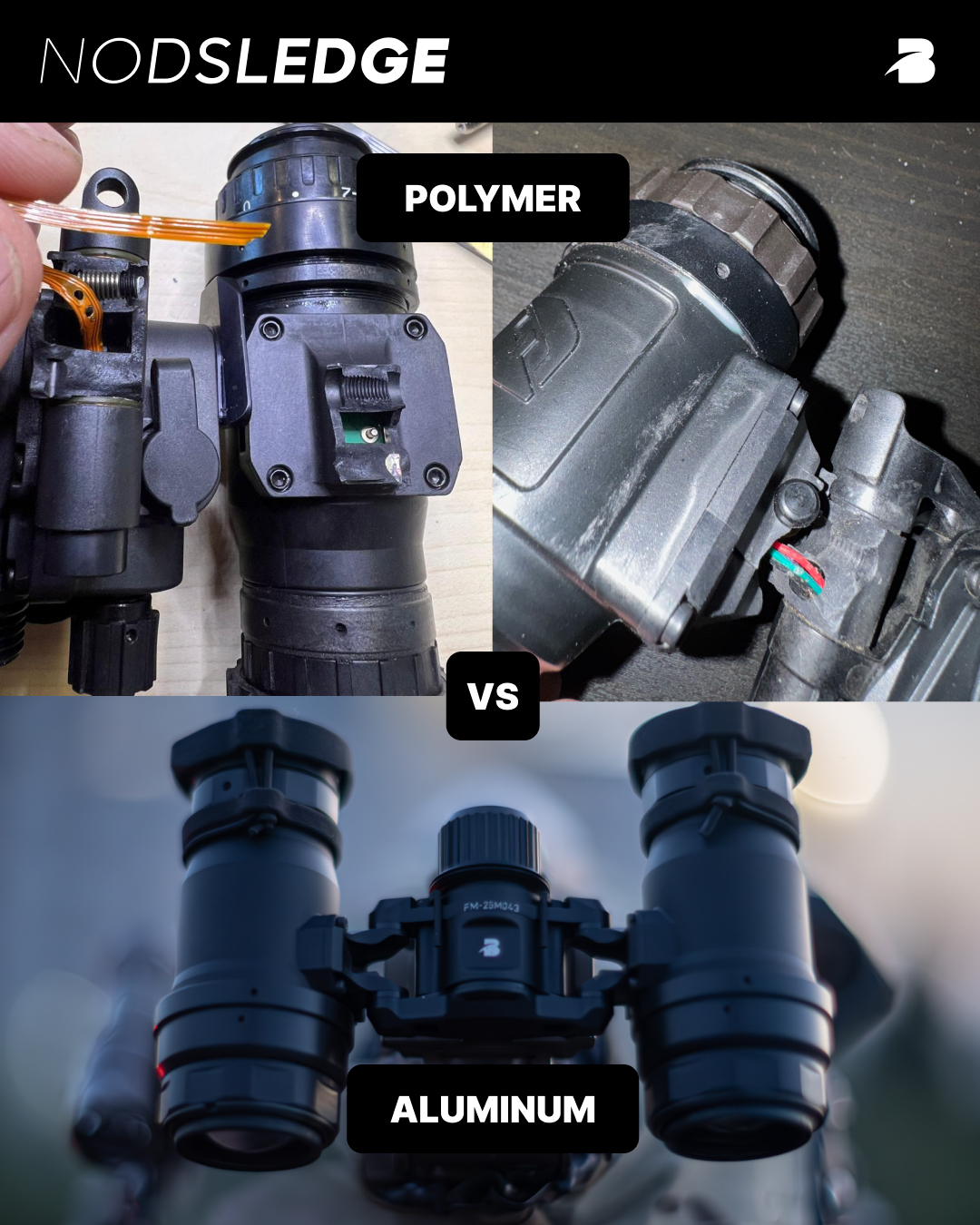

NODSLEDGE – ALUMINUM vs POLYMER : A PRACTICAL COMPARISON

When discussing night vision systems, most attention is given to optics, features, or battery life. But one critical aspect is often overlooked: the structural material of the housing. Whether the device is used in military, professional, or independent settings, its ability to withstand impact, maintain optical collimation, and be serviced in the field depends directly on the material it’s made from. Should one prioritize the low cost and lightness of polymer, or the mechanical reliability of aluminum?

We approached this question pragmatically, based on real-world field use.

A BNVD 1431, broken at the hinge during operations on the Ukrainian front. Credit : Nikita Bordeniuk – @patriotoptic on Instagram

When we designed the Proton Lite, the initial objective was to have a simple, low tech, high feature, field-serviceable night vision housing. As for materials, we chose 7075‑T6 aerospace-grade aluminum, chosen for its exceptional strength, rigidity, and resistance to long-term mechanical stress.

Besides the structural advantages of aluminum, this material allowed us to bring two additional features to the product.

- Standalone parts with a solderless design, which make field replacements possible without specialized tools. There are basically only 5 main parts on the bridge : the two hinges, the front and back bridge assemblies and the button / battery cap.

- An internal architecture where the housing itself is part of the electrical circuit, eliminating the need for wiring and potential points of failure

This approach does raise production complexity and cost compared to polymer housings, but we work hard to keep pricing within the range of other entry-level housings.

When choosing night vision systems, the structural material isn’t a minor detail, it affects durability, optical alignment stability, and reliability under tough conditions.

Many entry-level and high-end NVGs often use glass fiber–reinforced high-density polyethylene (HDPE-GFRP). It’s lightweight, moldable, and inexpensive to manufacture, especially suited for large volumes in military procurement programs backed by strong replacement logistics. However, when it comes to durability, HDPE-GFRP doesn’t shine as much as aluminum.

Purely speaking in terms of mechanical properties, aluminum has a notable advantage : Yield strength

It is the maximum stress that can be applied to a material before it changes shape permanently and will not bounce back. HDPE-GFRP has a yield strength comprised between 19.0 and 82.7 MPa whereas aluminum 7075-T6 has a yield strength comprised between 430.0 and 780.0 MPa. If we keep the maximum yield strentgh of HDPE and the minimum of 7075-T6 aluminum, the latter is still more than 5 times stronger!

On top of that, aluminum is also a lot stiffer and does not bend as easily.

Plastic housings tend to be naturally less stiff than aluminum ones.

How does it translate to real life NVG usage ?

This flexibility in plastic housings leads to deformation, which can compromise optical collimation, especially after impact or prolonged pressure. In worst-case scenarios, the housing can even crack or break. The most common failure point on articulating NVGs is usually the hinge.

Another Polymer housing, this time a Theon Sensors Unit. Broken at the hinge again. Credit : Nikita Bordeniuk – @patriotoptic on Instagram

Of course, aluminum is also heavier than plastic, but through smart design choices, we can achieve similar or lighter housing weight than some polymer products.

In situations where users don’t have access to reliable logistics, or are paying out of pocket, an aluminum housing is not a luxury, it’s a rational choice.